Buying and evaluating motorcycle gear

While it's typically pretty easy to walk into a bike shop, and walk out, usually a few hundred dollars lighter, feeling like you've bought something 'substantial,' doing a lot of research online leads me to believe otherwise. A LOT of gear today, like other things, is coming out of China and elsewhere, regardless of the location of the 'brand' you're buying, and as always, it's about someone, somewhere, making a buck, not necessarily someone overly concerned with what might happen to you if you have to depend on their gear.

To further complicate matters, the US or DOT has no ratings for gear besides helmets, for impact protection, tear strength, or armor ratings, so that basically leaves us only with the EU CE standard for armor, or well, 'what the manufacturer decided to use.' Note that still doesn't cover tear or abrasion strength, but having said that, I won't buy *any* gear without it being CE rated, or being 100% sure it exceeds the CE rating for impact protection.

So, let's look at what might happen in the event of a crash, and what sort of forces would be at work. The two most likely occurrences are:

-

Failure of a rider to navigate a turn or keep his/her bike under control.

-

A motorcycle coming into contact with a semi-immovable object, like a vehicle turning left in front of him at an intersection.

Obviously, either are to be avoided, but think about it. You're pushing too hard, or have to do an emergency maneuver, and you low-side, or worse, you high-side on the bike.

A low side happens in turns, and the bike slips out from underneath you around a turn. You may or may not remain with (or possibly under) the bike, but roughly, something like this happens:

-

You lose control around a turn, and the bikes wheels slide out towards the outside of the turn, and you and the top of the bike head towards pavement, while there is still forward momentum

-

An impact occurs, possibly including your helmet, gloves, elbow, and side of leg, foot/ankle.

-

Sliding occurs until the bike and rider are stopped, likely on the legs and arms and hands, with gear sliding against the tarmac. Secondary impacts may happen between rider and bike, or rider and road if he/she starts to tumble, followed by finally sliding to a halt.

So, we've got initial impact. In the above case, obviously impact protection as well as abrasion come into play, plus material tear strength on each impact or event, although my personal opinion is that tear strength is secondary to impact protection and abrasion strength...plus seam strength while sliding, hopefully ensuring the gear doesn't come apart at the seam. Without good armor inside your gear, it's very likely you can hurt yourself from the impact alone, or having a body part touch down between the ground and the bike itself. Again, ankles, knees, and hands don't take much to damage them. Ribs are also often hurt, usually on initial ground impact or by the bike's handlebars or fairings themselves. Secondary impacts may occur before stopping, as you may wind up rolling or bouncing. Granted, that secondary impact may seem like Snell has the right idea with their helmet testing, but regardless, you want your gear to hold up to possibly additional impacts. Once the rider 'settled' somewhat (not bouncing), the rider is likely going to be sliding a bit further until they stop.

One a high-side, where the rear wheel loses traction, then regains it, the bike will want to 'upright itself, forcefully,' often resulting in the rider being thrown up over the top of the bike in the opposite direction to the one they were leaning into for the turn. In this case, the initial impact is very likely to be greater than in a low-side, followed very frequently by rolling or bouncing, with other secondary/multiple smaller impacts, as well as some sliding before coming to a stop.

When another vehicle is involved, things can get more complicated, and the rider's bike stops rapidly coming into contact with another vehicle, one that is often stopped or at low speed, and the rider has rapid deceleration. It's frequent assuming the front of a bike contacts the other vehicle, for a rider to do a 'superman' and is thrown over the bars or clip-ons, launched into the air in the same direction the motorcycle was originally moving in.

However, the presence of a vehicle directly in front of that path now, tends to be bad news. If it's lower speed, a rider may not be launched entirely off the bike, or may tangle up in the bike's bars against his/her ribs or legs. A 'superman' usually involves a head impact that can be more significant for example, than a low-side. While vehicles today are built to have crash protection in the form of crumble zones, and a car door will have some give, which may lighten the loads slightly over for example, hitting a brick wall, the forces involved give a relatively soft and light-weight object (rider and/or bike) with a lot of kinetic energy built up from the speed prior to impact. The major factor here, assuming one does not get thrown entirely over the vehicle, or go underneath, is in impact protection, and possibly material tear strength, if an oddly shaped object is impacted. It's also common enough for a rider to do a superman right over the vehicle, in which case, the accident can resemble a high-side as described above.

Ok, what does that all mean, though?

Basically, that there's more to buying protective gear than finding some random jacket or Joe Rocket piece of gear on sale. This could be your life, do you really want to trust it to a piece of bargain gear?

As DOT has no standards for protective gear, the European CE is all we've got to go by for armor. Most manufacturers are worldwide for distribution and sales, or at least more than the US only, so without a damned good reason to explain it, I wouldn't buy gear non-CE level 2 rated. And there's tons of it. From back protectors, jackets, pants, even boots can have CE rated armor, or not. And much of it does. Next time you're browsing the bike shop, take a look at the mesh or other jackets - if it's CE rated, it will identify itself as such on a tag. What about the back protector? In many jackets, this is a simple piece of thin foam..do you really think that will protect you much, if it needs to? I've seen a fair number of jackets with CE elbow and shoulder armor, but a very cheesy non CE rated back protector. CE ratings for back protectors can have two levels of certification, level 1 or level 2, with level 2 dealing with higher impact forces. Again, would you prefer a thick piece of foam, or something like this CE rated, anti spine reversion back protector from Knox, or others?

aegis8sm_textmedium

The first image below is a standalone full back protector, and to date, it's unlikely to see something quite as substantial inside a jacket bought off the rack. Even so, you can do much better than the thin foam used by many, non CE rated. This is a CE level 2 back insert that is frequently used in Teknic jackets and others, off the rack, and purchasable separately for jackets that don't have a CE rated back armor. The standalone actually helps stop the spine from ‘folding over backwards, while obviously the typical jacket insert has no real structural rigidity so it limited to impact absorption and sliding protection (mostly from the outer covering layer of the jacket enclosing it..).

Note that even if you have to go with a 'low frills' jacket or pair of pants, many pieces of gear the armor can be pulled out, and replaced with CE rated armor; here's a link to some replacement armor, or just search for 'CE replacement armor' and you should be able to turn some up.

Nowadays, even low end brands like Joe Rocket (sorry, they are, Google 'Joe Rocket crash' to see how well some of their gear does not hold up, I consider JR the Wal-Mart of gear, even if at times it looks decent enough) offer CE armor in their gear, or offer replacement armor at additional cost.

Even replacement CE armor isn't all the same. Check your gear, and make sure the new armor will slide in without issue, or bring it to a tailor if need be, to have it sewn in. For back protection, you can always remove the jacket supplied foam or armor, and go with a full protector as shown above, with it's wast and chest straps, or at the very least replace it with a CE Level 2 replacement.

Remember when buying gear that it should fit fairly snugly, as that is part of what holds the armor itself in place against your body. Armor that slides away from you when it's needed isn't doing it's job, or at least not offering full protection to the areas it was meant to. On a jacket, you should decide what the most layers you'll wear underneath will be, preferably performance heat and cold gear like that offered by UnderArmour and others, which include very thin (comparatively) thermals for colder weather as well, allowing you to keep the jacket fitting snugly, but still being able to layer up a bit for warmth in cooler weather.

Many jackets come with a zipper intended to zip up to pants, forming a kind of ‘one piece’ when desired. While a full circumference zipper is desirable, or a one piece suit, this isn't always feasible for all of us. Sadly, the manufacturers seem to intentionally make sure their zippers are incompatible with other manufacturers gear, however, so your new Rukka jacket may not zip to your BMW or FirstGear pants 'out of the box.' However, most jackets do include the lower portion of the zipper as well, so you can have it sewn on by a tailor. Think about sliding down the road with a jacket on, feet first, and it becomes obvious what the zipper is meant to do - to keep the jacket in place, protecting you, instead of sliding up.

What gear do I need?

That's a personal opinion, but I’ll give you mine, noting that helmets are required in most places, with the rest being 'optional' by law.

My personal belief, which seems to match mostly with others, is in order of priority - in others words, if you're unable to get it all at once:

-

A good quality helmet. My preference is DOT/ECE, not Snell - I had a link to a great article by Motorcyclist, but it’s now offline :( A head impact is nothing to sneeze at, and Snell helmet ratings, unless updated - just didn’t leave it as an option. When buying, check for the latest standards applicable, as occasionally some standards updates are made, and in general - usually for the better.

-

A good quality jacket, with CE Level 2 armor, appropriate for the conditions you'll be riding in. Again, you've got some fairly important parts covered by a jacket - your back, chest, ribs..

-

A good quality pair of gloves. Hands are easily damaged, and often come into contact with the ground in a motorcycle accident. Yes, some gloves are bulky, and with most, you lose some amount of 'feel' to the bike, but, consider the alternative.

-

Quality boots. Ankles are very easily broken, and quite often a bike can fall onto one in a low-side, or even accidentally tipping over off the kickstand. Sneakers, sandals, or anything not covering your ankle is simply an accident waiting to happen.

-

Pants. Knees are also easily broken, and quite likely in an impact that knees will be impacted, as well as in sliding or rolling/bouncing.

Leather or textile gear?

This one will likely cause some disagreements. Leather is the traditional material of choice for motorcycle and other protective gear, and hey, it even smells and looks good (some more outlandish bike jacket designs excluded from the latter!).

Leather does have excellent abrasion protection and good tear strength. A variety of types are available now, from the 'normal' cowhide, kangaroo, deer, and more hybrids are becoming available, mixing in Kevlar or other synthetics.

Leather is good stuff, but it's not the whole story. A quality leather one piece suit or jacket, without armor, or without good quality armor, might save you from quite a bit of road rash, but what good is that if on impact, you wind up with a broken kneecap or elbow, or worse? Low end leather gear may look good, but again, like with anything, check the armor - it's rating (or not) and coverage.

Leather does not do well in the rain. It can take days to dry after being soaked, and using heat to help it dry can degrade the leather's performance..not something you want to do with protective gear! The best thing is to simply let leather dry itself, with the aid of a fan (not hair dryer or heat), and some people stuff towels or newspaper inside to help it hold shape and dry sooner, then followed by a leather conditioner. Note - saddle soap is not recommended, as it can dry out the leather, ironically, but it can be used for spot cleaning if necessary. You want something that is non-alkaline, like a small amount of Lexol, or Mink Oil, or a quality conditioner. Mink oil will have the advantage of making the leather a bit more water resistant, but don't overdo it.

Leathers can also be quite hot, but perforated leather is available. It may lose some tear or abrasion strength due to perforation, but as long as you're moving, many wear perforated leather gear up into the 90*F range. Leather will generally take some time to break in to conform to your body.

So, what about textiles/synthetics?

Textiles have a few advantages over leather - cost, can be waterproof, color choices, and can also be lighter weight. However, having said that, some of the same caveats can apply. New materials are becoming available that work both in high temperatures as well as low. Textiles can be affected by UV, just like leather, and can color fade over time. More importantly, there is a lot of crap textile gear out there (although there is some crap leather out there as well). With the armor being equal (not always the case), and temperatures being within reason for either, I'd generally pick a good piece of leather gear over textile if protection were the only concern, with a few exceptions..(see discussion on MotoPort later), but many of us don't live in an ideal world where we have multiple pieces of gear on hand at the same time (or can afford to do so!). Textile is more versatile in 'all weather' year round conditions, including rain via liners (although you can also buy Frog Toggs or an outer rainsuit to put on over leather), but again, simply having good armor isn't the whole story if your new Joe Rocket textile jacket falls apart on you when you need it most.

Manufacturers even of leather gear can opt to 'cheap out' on their stitch material, or how the seams are joined, so even with the best material panels and armor, a slide could result in your gear falling apart.

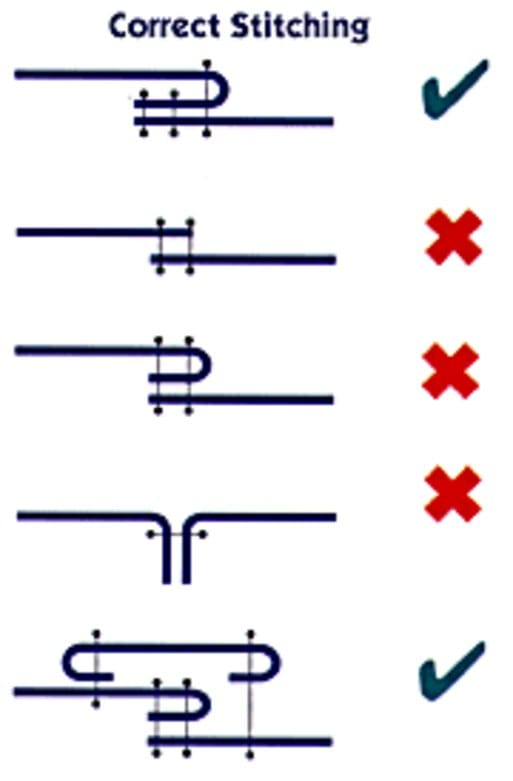

In the image to the right, image originally from DCSportBikes.com, showing stictching options, note the fourth stitch down, this relies entirely on thread strength alone for the seam, and may also easily simply pull through the material, as it's stitched in the same plane of any stress on the seam (plus in this case, a single stitch as well)

The third down isn't so bad, with the 'tucked' down section ensuring the material is strengthening the seam, creating the third layer and a thicker seam, but most quality leathers today use triple stitching, as shown in the first stitch diagram, or more, as shown by the last. Additionally, you want at least some of the stitching to be protected by being underneath another layer, so the stitching isn't immediately worn through at the start of a slide (the main issues in both 2 and 3, besides only 2 stiches per seam).

Even if the stitch itself is done properly, you don't want to have a piece of gear with weak thread for the stitches, but unfortunately, it's often quite difficult to find out how most jackets are constructed in detail, and some gear while it may look fine, people may not know until they need it. Do your homework on gear, no matter what brand or type you purchase!

Some pictures of failed gear, of several 'known' makes. Note that in some situations, damage to gear is to be expected, and perhaps destroyed, but to protect you. If your entire jacket falls apart at a relatively low speed of 20MPH in a low-side, though, how confident would you be in it at more normal speeds?

An AlpineStar suit after a lower-speed accident (again, original credits to DCSportBikes.com on the images) - at least it looked nice…until it was needed.

Should I get a textile suit, then?

Not really, or at least not yet. Leather is still generally ahead in abrasion, by quite a bit over most off the shelf textiles, whether one or two piece. Cordura and derivatives aren’t bad materials, but it's abrasion resistance (time to wear through it in testing, or a slide in real world..) is significantly lower than leathers. Adding additional layers of Cordura can help, yet even today most vendors selling Cordura based gear are still using Cordura 500 denier, while Cordura 1000 and Cordura 2000 are available (think of Denier as fabric weight or density, usually leading to better abrasion resistance).

According to a BMW catalog:

""Cordura 700 is able to withstand crashes at road speeds about 20% higher than Cordura 500."

Dynatec is "extremely tear- and stretch-resistant (at speeds up to approx. 50% higher than Cordura 500.)"

GORE-TEX Armacor "displays excellent abrasion characteristics thanks to Kevlar® (approx. 100% improved crash resistance compared to Cordura 500.)"

Dynatec I believe is a blended material. It's difficult to keep track with all the ‘brand-special naming’ of materials, and note even the wording used is vague - referencing speeds versus actual abrasion resistance like the CE tests perform. Armacor is another recent material, and is essentially a kevlar and Cordura blended material, having better abrasion resistance over both Cordura and Dynatec.

Other advances like Outlast linings help to regulate your core temperature, meaning you can be out in cooler or warmer weather with less ill effect, while materials like the Hi-Art material used by Halverssons, Motoports kevlar blend suited, and T-Pro or ForceField Armor, all show promise at either coming close or surpassing the protection of leather, and making gear more comfortable.

While there are some interesting things that are happening with textiles, sadly, we're not exactly 'state of the art' in protective gear just yet. The majority of textile gear found at your local bike shop may or may not hold up as well as you'd like, and like most gear, it's a compromise, as most of us can't easily commute in skin tight race leathers, and we don't particularly want to get soaked when it starts to rain, either.

Leather equipped with the same armor as textiles, and good seams, will nearly always outperform standard textile gear. There are a few possible exceptions, notably the Halvarrsson Safety Suit and Motoport's Kevlar gear. The Rukka SRO Anatomic also seems promising, but none of these are inexpensive pieces of gear.

Editor note 10/2020: Specific models have changed since the orginal writing - unsure if Halverssons or Outlast have been superceded at this point, but the armor and thread, as well as comments on Denier vs kevlar and leathers - remain true today.

The SRO and some of Rukkas other gear, as well as the Halverssons Safety Suit includes an Outlast lining, which actually helps to regulate your core temperature in both cooler and warmer temperatures. Outlast underwear can also be purchased. Neat stuff. People using it say it does indeed work, perhaps not quite as they'd like, and while it does balance out your core temperature, it also doesn't alleviate the need for warmer/more layers when it's truly cold outside, nor will it allow riding in a thick jacket when it's hot out, but for the non extremes, it seems to have an affect.

The Halvarssons Safety Suit below is two pieces, with the left is the inner liner, which contains CE approved armor, and the right is one of several shells that can be worn over the inner suit

The Motoport Kevlar Mesh or Ultra II (custom fit, can be purchased as one piece stretch kevlar or kevlar mesh suits or two pieces, with 3/4 or waist cut jackets) is another option, in this case, US-based, and was the first non-leather gear approved for racing. It’s not inexpensive, but has numerous jacket style and armor options.

Shown on left is their waist cut GP2 Stretch Kevlar jacket, and Air Mesh pants on the right). Combinations or full stretch or mesh material are available.

Finally, there are a few other interesting options out there. I did come over time to appreciate RevIt gear, or at least their gloves - and would consider checking out what they offer today. Rukka has always made some expensive, but seemingly reputable and solid, and honestly - not bad looking gear. In 2020, Klim has also had a growing fan base, and they seem to be making some expensive, and possibly decent alternatives, but I haven’t laid hands on one of their recent offerings.

The Rukka SRO, likley replaced by a newer model (by 2020) is a damned nice looking jacket, and I’d be interested in seeing how they progressed in construction and protection.

There's a saying the best gear is the gear that you'll wear...

When it comes down to it, that's very true. While not as protective (in general) as a leather one piece suit, there have been plenty of people having accidents in textile gear, that came out fine, or significantly better than had they been without gear.

If you decide textiles are for you, whether due to commuting, or range of temperatures, the best you can do is look for double or more layers (or leather) on prime contact areas (elbows, shoulders, wrist area/forearms, knees, thighs), and make sure the armor is CE approved (again, ideally Level 2), and has decent seam strength. Look at the quality of stitching, and give it a tug in the store. If it feels like a seam will give from you pulling on it, it's unlikely to fare terribly well when you need it most.

Abrasion resistance, tear strength, seam strength, HELP!

Think back to the discussion of forces in play against gear from the accident scenarios earlier, and about what gear does, or should do, and these terms should make sense.

Abrasion resistance is for a given force rubbed against the material, how long the material will survive before wearing through. Leather has very good abrasion resistance compared to most other materials available for clothing today. Your pair of shorts or jeans have nearly zero for all intents and purposes.

Tear strength is a measurement of force needed to be applied to rip a material.

Seam strength is more than simply the tensile strength of any stitching used (although that is a part). It's effectively how much force must be applied to get a seam to split, or burst.

Unsurprisingly and unfortunately, the US and DOT do not specify any testing criteria for motorcycle protective gear, outside of helmets. Wouldn't it be nice if some portion of my tax money went towards setting and testing such a standard, as I do indeed both pay taxes and ride motorcycles? :-/

The EU, thankfully, does have some certifications and testing procedures defined. Not only for helmets, but also for protective armor, full outfits (meaning jacket + armor or pants + armor), as well as even for gloves. Unfortunately, it is not mandatory to meet these requirements to sell gear, and some vendors play some wording games as to which, if any, certifications they meet. The CE standards are multiple level, and can be applied to armor or an entire piece of gear.

While formulation of a standard testing procedure may be debated as to effectiveness, or whether it's an accurate representation of real world accidents or not, it's certainly better than simply 'hoping for the best' when you buy a piece of gear.

Some vendors will claim their armor, or gear, or worse, they'll be vague on which, may 'meet or exceed CE specifications.' Well, that's nice, but that does not mean their gear has been certified by the testing bodies. It's basically them telling you ' -'it's protective.' Companies often use another vendors armor, such as Knox, or T-Pro, at which point they can indeed say the armor is certified. Back protection should ideally meet Level 2 (average of multiple impacts of 50 Joules may not transfer 9kN), or EN 1621-2 , but many vendors still either use non-CE rated/certified armor for back protection, armor meeting EN 1621-1 (Level 1, average of multiple impacts of 50 Joules may not transfer more than kN of force through the armor), or include no back protection at all!

The full CE specifications and testing requirements may be found here (the above numbers/tests are part of, but not the complete set of tests):

CE Standards

As an example, even the very expensive Rukka gear at best has CE certified armor, yet their jacket is not CE certified, nor is Motoport's gear (although some of it is sanctioned for race/track use, the only synthetic suit to be allowed, as far as I'm aware), while Halverssons Safety Suit in entirety - it's armor and jacket or pants are full CE certified (although I don't recall which level(s) offhand).

An excerpt from the CE link given above:

"Under the EU Standards, material used in motorcycle protective clothing must have abrasion resistance of between 4 and 7 seconds for use over the high impact areas of the body (Zone 1 and 2). Just to put this in context, a single layer of 1.4 mm cow hide will last 5.8 seconds, while 200 gsm denim (or your standard jeans), will last just over half (0.6) of a second (SATRA, 2002).

Tests conducted at the British test laboratory SATRA (SATRA, 2002 and at the Melbourne Institute of Textiles (Standards Australia, 2000), found many of the modern textile alternatives fail to meet the standards when tested as a single layer."

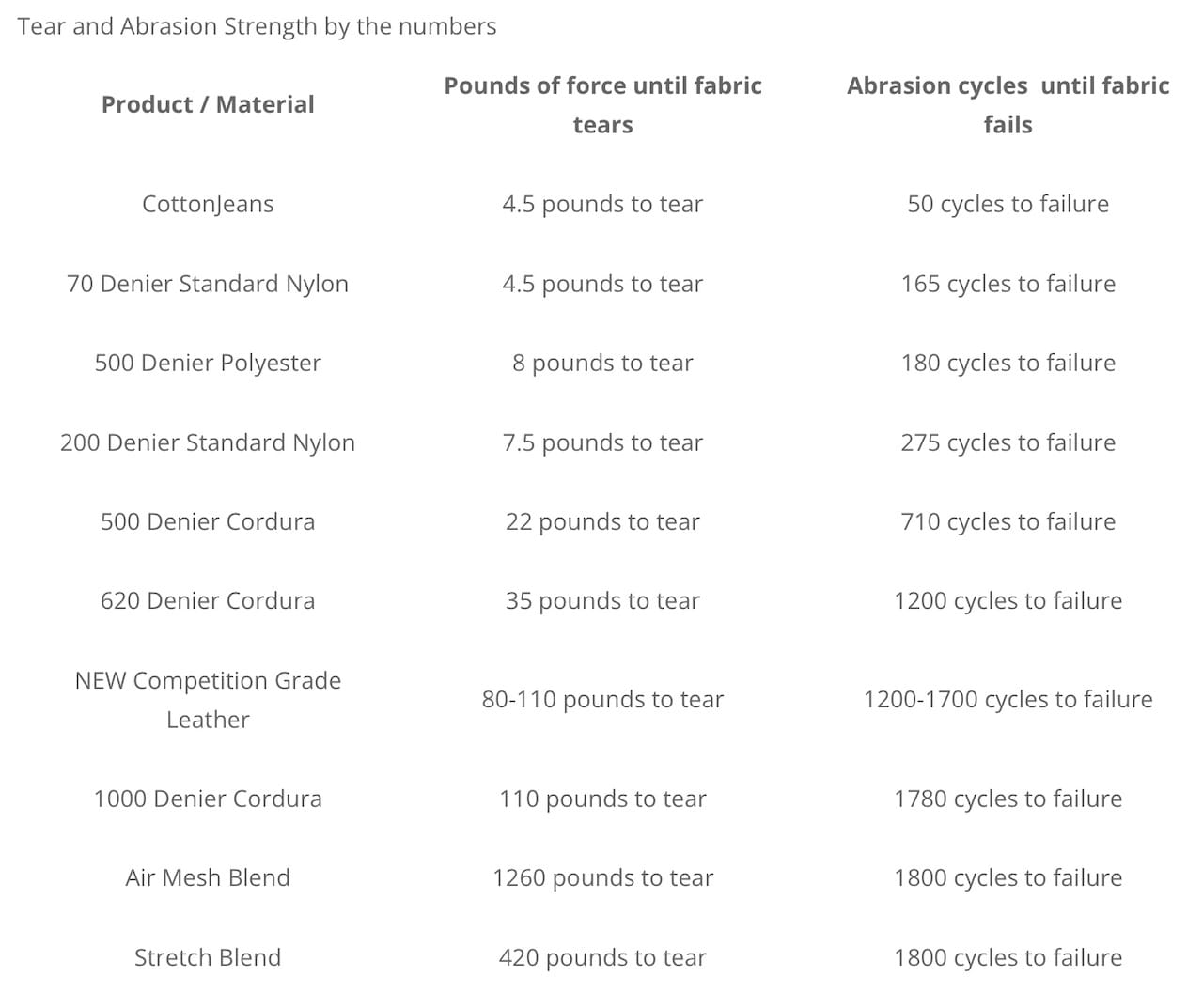

To give a bit more context to the differences in materials, from Motoport, Tear and Abrasion Strength by the numbers

Unfortunately, Motoports numbers aren't given in seconds, nor as far as I know, is their test procedure documented in any way that would allow direct correlation to the CE test procedures or numbers, but yu can get an idea compared to the different materials.

Seam strength testing is also tested as part of the CE certification, called 'burst testing.' It measures the amount of force required to well, burst the seam open, in a piece of gear.

Now, given the choice, would you rather have a piece of gear that is fully CE certified, knowing it meets a minimum requirement for several areas/forces related to impacts and accidents, or hope that Mr Joe Rocket has your best interests in mind over corporate profits, and that JR gear would pass any of the CE specified tests?

So, in short, choose your compromise carefully. Textiles can be nearly as, or as good as leather in some cases, and more livable for casual/road riding, but poor construction or materials, even if it looks good, can lead to unexpected and perhaps disastrous results, and until mandatory gear testing is a requirement for all vendors selling motorcycle gear, vendors test and release test information to the public, or some party steps up to test all the available gear and publishes it, purchasing any gear not CE certified can be a crap shoot, and doing some research on it as well as examining it, and applying some common sense, is in your best interest. At the very least, make sure you have CE rated armor in your gear, whether leather or textile, and the gear fits you properly.

What About Mesh Gear?

For many of us living in areas with high heat and/or humidity, wearing a full set of leathers, or an Aerostich suit, isn't terribly appealing, as the former may feel and be protective, and the latter may feel protective and be waterproof, but either one are likely to make you sweat profusely and be quite uncomfortable at temperatures over 80*F or so.

Of course, most of us have seen mesh jackets like this one below, and thought 'Wow, that would be great for warmer weather!'

And indeed, they are, while riding on the bike. However, nearly all mesh is made of either polyester or nylon, neither of which is very strong, and also has very low abrasion resistance. Do some Googling, and like most gear, you'll find some saying 'my jacket disintegrated!' as well as some stories saying the gear held up fine.

As shown above in the table, Motoport Kevlar mesh may be the exception to that rule, and indeed, I've gone down wearing their pants, with no damage to myself or the pants as a result.

Overpants? Or..how do I commute easily?

For people that commute on their bikes, we've got the added burden of having to wear nicer clothes than we might for a simple day of riding, as well as a desire to have those clothes be at least fairly presentable once in the office.

Latops can be carried easily enough in a tail, saddle, tankbag, or backpack, but it does make wearing a skin-tight one piece leather suit a bit tougher. Some still do, and simply bring a change or clothes, or keep a change of clothes at the office. Others wear an overpant, or something like a Aerostich Roadcrafter one piece textile suit (warning - the Stich isn't suitable over 75-80*, however, unless you'd like to show up to work soaking with sweat!). Pants are either meant to be worn alone, with underwear, or as overpants, over your normal clothes. Take this into consideration when buying, which type works best for you. (Although note, as a general rule, snugger/tighter gear is preferred, to retain armor in the proper place..don't get something too large!)

One Piece or Two?

Again, much of this will come down to personal preference. Two pieces in general are more convenient, and indeed, getting into a one piece set of leathers can take some contortions, as it's meant to fit quite tightly. A one piece doesn't have the possibility of pants sliding down, nor the jacket riding up, exposing you to the possibility of road rash. Most jackets nowadays come with at least a small zipper, with the matching end attached, meant to be sewn onto your pants, so you can zip the two together. While a full circumference zipper is preferable, even the addition of a relatively small connection between jacket and pants can go a long ways to avoiding road rash in the event of an accident. Any tailor should be able to attach the zipper onto your pants for a small fee.

Hybrid Gear

More frequently, we're starting to see jackets that are both leather and textile. They may have mesh in some parts, with leather, or kevlar blended material at the typical impact points on top of the armor, in single or multiple layers, similar to the jacket shown below (although the one below doesn't have leather on the elbows).

L2ltYWdlcy9wcm9kdWN0L2xhcmdlL1NILTAwMzYtQmxrR3JleV8xMTU4ODgwMzk1LmpwZw==_H_SH315_MW355

I think this idea has some merit, but recall the diagram on leather stitching types? I'd be careful to inspect how the leather and textile are stitched together before purchasing a similar item, something that really has to be done in person, via buying some unknown brand from eBay, unless you have someone you trust explicitly that has seen it in person, and knew what to look for. Again, this doesn't mean all of these types of gear are worthless, but there are construction issues to be investigated, like with most any gear, full leathers included.

So, I have to find CE certified gear, only, and all other gear is crap?

This is open to debate. While standards can be a good thing, there's also some concerns there about gear being built directly to pass some standardized testing, versus holding up and protecting well in a crash. You'll have to read the CE standards and come to your own conclusion. Personally, I think it's a good start, and would choose a fully CE (or Cambridge) certified piece of gear (entire piece, not armor only), over 95% of the off the shelf gear out there, whether leather or textile, but I also believe governments need to spend some more money on motorcycle crash investigation, as there simply isn't all that much data out there. The Hurt Report was complete back in the early 1980's, and provided some useful data, but very little real subsequent real research has been done since that's been published. Additionally, while the Hurt report and others have shown percentages as to which areas of the body or head are most likely to be impacted, I'm unaware of any helmet manufacturer that addresses this specifically in their helmet construction. And, why should they? Neither DOT nor ECE specifies chin impacts must be tested for helmets.

So, while standards are a good starting point, and I believe the CE certifications certainly have merit, even moreso over none, there simply is no guarantee. Because a piece of gear isn't CE certified, does that mean it's automatically garbage? No, not at all, however, it does seem to be more likely, and I'd carefully research it before purchase.

Neither Motoport nor Rukka have their gear CE certified, although Rukka in some case uses CE certified armor, and as far as I know today, only Motoport with their new quad armor, and Rukka, use Dow's new APS compound as a part of their armor, which looks promising, stiffening on impact. This is one of 4 layers on the Motoport gear, and I believe Rukka uses it in entirety, but in a vented/waffle type of form.

Conclusions

Motorcycle gear is advancing, although somewhat slowly in some respects, with no global nor even US specified testing beyond helmets, nor is it yet required even that EU gear meets the CE certification requirements. It's difficult to go on name brand alone as a 'guarantee' of protection, as new vendors come onto the scene and many are competing in the 'budget priced' arena, companies are bought and sold, sometimes unknown to consumers, and nearly everything is made in China.

Textiles are advancing, but quality and abrasion is a concern on all bu the most high end textile gear, such as Halverssons, Motoport, and possibly Rukka and BMW and others. Having CE certified armor is a good first step, but many suits themselves are not CE certified, so we often have no indication on seam burst strength, for leathers or textiles - even the best armor in the world does little if a seam rips open and the armor isn't where it's supposed to be!

Until such a time as all gear is fully certified, or comparable numbers are published that can be compared to other pieces of gear, like seam burst, abrasion, etc, the best we can do is research our gear thoroughly before purchase, search online for crash reports on the gear, make an education decision, and encourage vendors via email or phone to publish the relevant abrasion and strength data, or get their gear CE certified. This is one purchase that directly could affect your well-being, and is worth your time spent investigating before purchasing.

Ride safe, and enjoy the ride!

Disclosure

I've written a lot about safety gear, but I am not a fabric engineer, nor involved in the construction of motorcycle gear, but have done a lot of gear research, including significant time looking up different materials, magazine and other testing, as well as literally thousands of online discussions on gear and crash results. I'm a motorcyclist that has concerns about some of the crap sold by companies claiming to be protective gear, the proliferation of buzzwords that confuse buyers ('Titanium Poly Mesh' as an example - no such thing..), and the near total failure of governments, the US in particular, to do the required amount of testing and analysis and enforce that all gear sold meets a reasonable standard of quality and protection.

For my own gear, I currently wear Motoport Kevlar Air Mesh overpants, a Teknic Spider (convertible from mesh to waterproof/textile, CE armor including Knox back protector), Oxtar boots, and either RevIt or Kobe gauntlet leather gloves (year round). I have gone down wearing those pants, without incident, and while I like the Teknic jacket very much for convenience (single jacket year round), I'm not convinced the seams, nor the mesh, will hold up in the event I really need it to, so recently did more gear research yet again, before deciding on going with a Motoport Air Mesh jacket.

Having said that, I don't have any financial interest in any motorcycle gear company, nor does it matter to me what gear you ultimately choose, but I'd prefer to see people make educated decisions, versus blind faith that some randomly purchased eBay or local shop gear will truly be protective, and thinking that DOT or CE certified armor is the 'full picture,' when indeed, it is not, and worse, there are currently no requirements besides for helmets that a piece of gear must adhere to.

Other Reading:

CE Standards

Fitting One Piece Leathers (video)

Armacor fabric

Outlast fabric

Forcefield Armor

Rukka Motorcycle Wear

Halvarssons Safety Suit

RevIt website

BMW Comfort Suit

BMW Streetguard 2

Poly issues - melting